Application

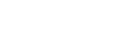

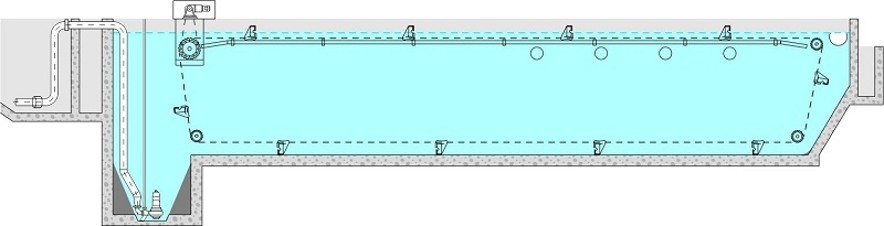

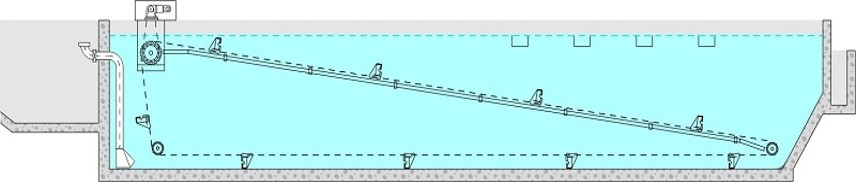

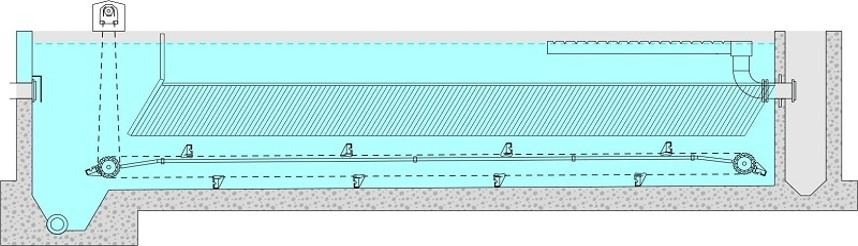

Chain scrapers are designed for the mechanical removal of bottom sludge and floating substances in municipal and industrial wastewater treatment plants. They can be used in rectangular clarifiers, grit chambers and DAF flotation units.

They provide a functional alternative to travelling bridge scrapers – particularly in facilities seeking a lighter solution that significantly reduces the load on the reinforced concrete structure compared to traditional bridges.

Scraper Types

- 4‑shaft scraper – for removing bottom sludge and floating debris

- 3‑shaft scraper – for removing bottom sludge

- 2‑shaft scraper:

for removing floating debris

for removing bottom sludge

Technological Advantages of ESMIL x Probig® Chain Scrapers

- Efficient sludge removal – chain scrapers continuously collect sludge and floating matter along the entire length of the tank, using multiple blades instead of a single travelling unit. This shortens the cycle time and improves process efficiency.

- Up to 10× longer service life compared to metal systems – achieved through the use of reinforced plastics (including GFRP, POM) and abrasion- and corrosion‑resistant polymer composites.

- Flexible configuration options – the system is individually adapted to tank geometry, hydraulic loads, and process requirements (including selection of materials, chain layout, and scraper type).

- Safe design – the lightweight, suspended scraper system does not generate additional static or dynamic loads, protecting the concrete tank structure.

- Up to 5 years of operation without inspection – scrapers are designed for long‑term use without the need for servicing; the first recommended inspection is only after 5 years.

- Easy adaptation to existing infrastructure – no structural changes or construction work are required, enabling rapid upgrades at lower capital cost.

Optional Equipment

- Modern plastic covers reinforced with fiberglass – effectively reduce gas and odor emissions and prevent the installation from freezing during the winter period.

Certificates

- ATEX (Atmosphères Explosibles)

The ESMIL x Probig® scraper system is fully compliant with the ATEX directive requirements for equipment intended for use in explosive atmospheres. The certification covers all scraper components – from the drive unit to the working structures – making us the only supplier on the market with full ATEX certification for the entire system.

- Compliance with API 421 (American Petroleum Institute)

The system meets the requirements of API 421, confirming its suitability for operation in environments contaminated with petroleum-based substances and under heavy‑industry conditions.