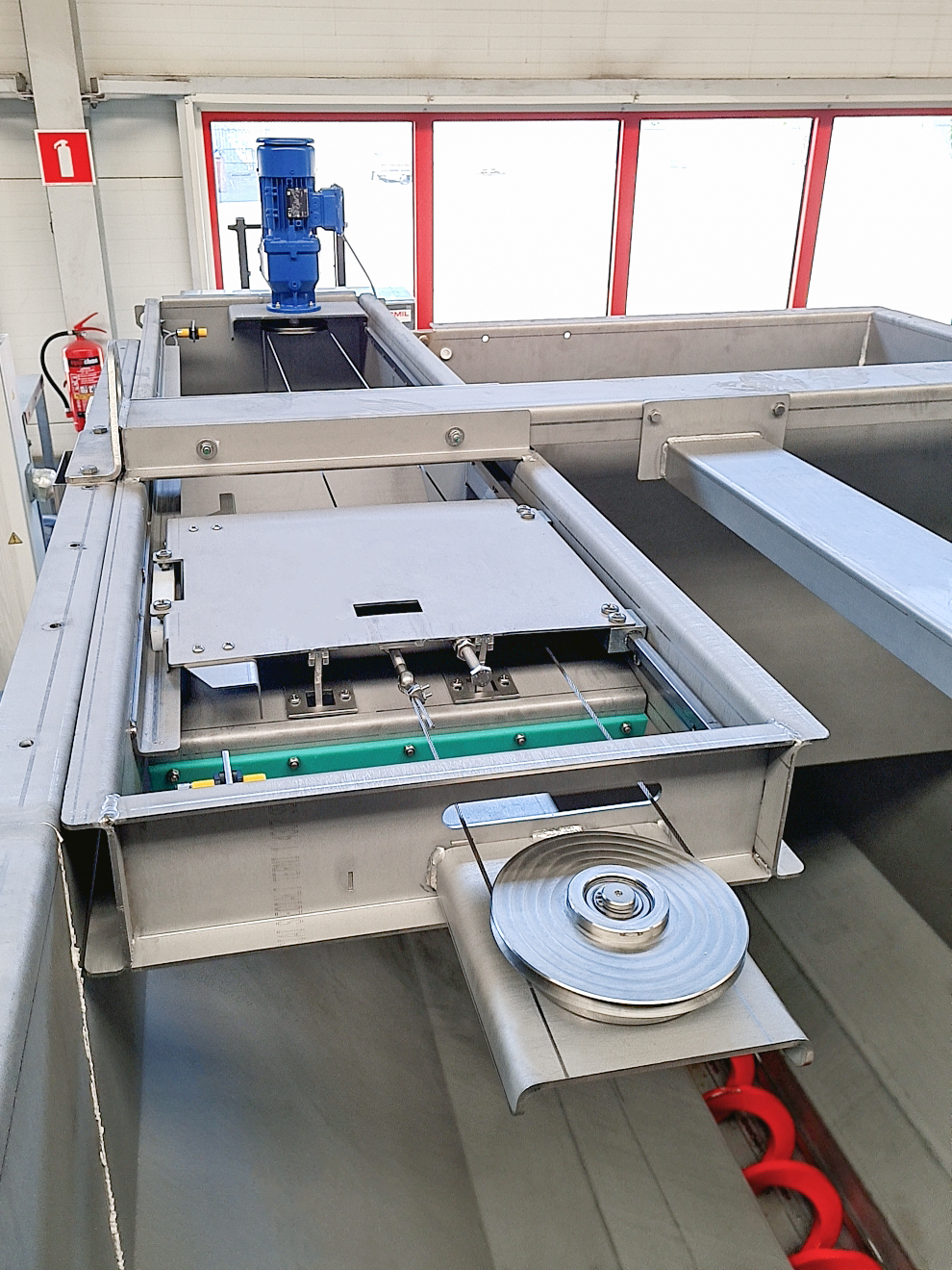

M-Comby Module is a complex solution for mechanical wastewater treatment for plants of small and medium capacities. It’s a compact module that provides all pre-treatment stages and ensures the effective removal of waste, sand and grease from wastewater.

The mechanical wastewater treatment unit M-Comby combines the whole range of equipment for

- mechanical treatment stages in one unit:

- fine screening,

- aerated grit chamber

- grease chamber

- sand washing and compacting unit.

It leads to significant space reduction for the equipment installation and therefore, the construction costs.

Key advantages of Combined Mechanical Treatment Module M-Comby

- Compact design leads to significant capital cost reduction for new WWTPs or during the reconstruction of existing treatment facilities.

- High treatment efficiency and successful operation are reached by the possibility of adding modules for the M-Comby Unit. Different types of screens design can be used for various waste removal regarding its type. Moreover, the unit can be additionally equipped with a washing device in case of specific organic content requirements.

- Debris and grit washing system prevents rot and the spreading of odors and allows transferring of organic compounds to further biological treatment stages if needed.

- Equipment flexibility. There are two different manufacturing options for M-Comby Unit: basic and modified (for example, with low-temperature protection or a bypass line with a manual screen). Equipment dimensions can be adjusted to the existing building. Due to its compact design, M-Comby has the best footprint among such types of equipment.

- Optimal organization of the installation site. Unloading of garbage and sand can be implemented both in containers located at each unit and in conveyors that collect sand and garbage from several units and transport them to the accumulation zone. This allows you to reduce the required floor space.

- A long lifespan of the equipment is achieved by the use of high-quality materials such as SS AISI 304, 316, 321. Etching, passivation, sandblasting are used for the stainless steel surface treatment. This considerably improves the corrosion resistance of the equipment.

- Operation and maintenance cost reduction is achieved due to the high automation level. The control system allows to operate the complex both in manual and automatic modes. Operating modes and parameters are intuitive and can be easily adjusted by the personnel demanding minimal attention. The control system can be equipped with additional modules for remote access excluding the necessity of the continuous presence of personnel at the site.

- Suitability of operation and maintenance. The use of high-quality components and time-tested technical solutions ensures a long lifespan of the equipment and minimizes the need of servicing. The design of the unit is convenient for carrying out preventive maintenance and replacing wearing parts. The main parts of the equipment are easy to access and their maintenance is carried out using ordinary tools.