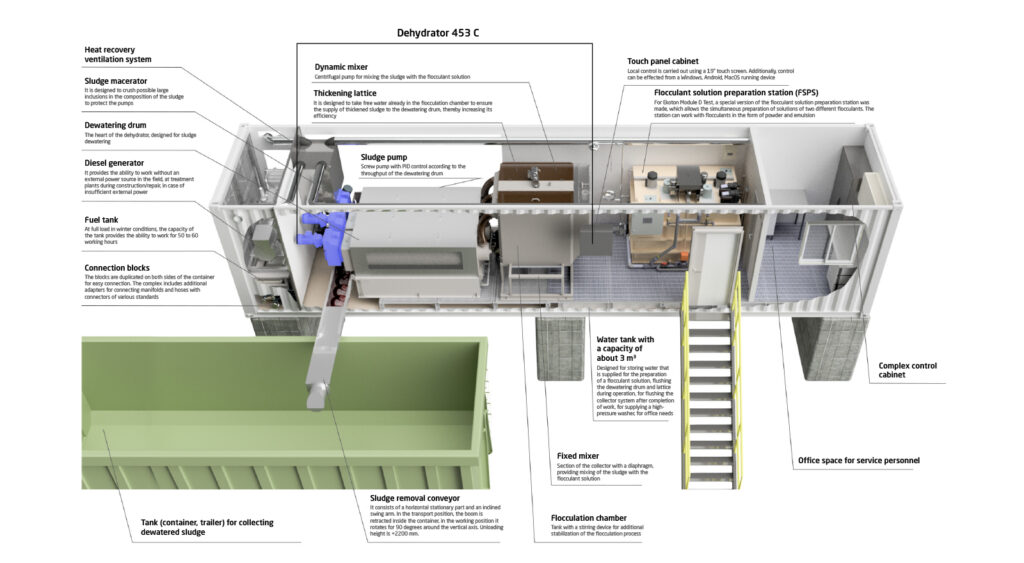

Containerized Mechanical Dewatering Plant based on multi-disc screw dehydrator MDQ Esmil Tsurumi.

Esmil Module D mobile mechanical dewatering plant is a new series of mobile plants for dewatering industrial and municipal wastewater sludge, supplied in standard 20 feet or 40 feet containers. The dewatering technology is implemented using the reliable and highly efficient MDQ Esmil Tsurumi multi-disc screw dehydrator.

What you need to do to commission the installation, is just to connect the module to feeding systems and select the operating mode (set-up, start-up). Depending on the performance and intended use, the Esmil Module D complex can be used both as a mobile complex and as a fixed installation.

The high degree of automation and the ability to remotely control the module eliminates the need for highly qualified maintenance personnel, while the modular design reduces capital costs.

Scope of application of Esmil containerized complexes for mechanical dewatering:

- wastewater treatment plants;

- water treatment plants;

- food and processing industry;

- biogas complexes;

- oil and gas industry;

- … and other industries.

What tasks does the MODULE D dehydration complex solve?

- Dewatering of industrial sludge;

- Dewatering of sewage sludge;

- Pilot and industrial tests;

- Increasing the performance of existing treatment plants;

- Dewatering of sludge at several sites or outside of fixed wastewater treatment plants;

- As a temporary solution: during the reconstruction of treatment plants, repair of out-of-order equipment, etc.

Advantages of Esmil Module D mobile mechanical dewatering plant:

- Ready-to-use equipment.

All equipment that is a part of the mechanical dewatering plant is mounted in a container at the Esmil production facility. The installation arrives at the site completely ready-to-use: what you need to put the plant into operation, is simply to connect it to the existing utility networks and configure the parameters of the equipment operation (plug-and-play technology). - High dewatering efficiency.

The sludge dewatering technology is based on the MDQ Esmil Tsurumi multi-disc screw dehydrator, one of the most reliable and efficient types of dewatering equipment on the market. The standard size range of dehydrators includes more than 20 models, the capacity of one piece of equipment is from 0.05 to 200 m3/hour (from 3 to 3780 kgDM/h), which allows meeting the needs of both large enterprises and small treatment facilities. - Minimum need for designing.

The product range of mechanical dewatering complexes has already been designed and developed, there are all the certificates for the equipment, the only thing you need to do is to tie a ready-made solution to the project. A ready-to-use solution allows you to reduce the time for design and approval of documentation, as well as the associated costs. - No odors.

The Module D mechanical dewatering plant can include an air purification system, which will minimize the sanitary protection zone. - Simple and easy operation.

All equipment is fully automated, there is an option to control the dewatering complex using a smartphone. Flexible settings of the parameters of the technological process allow you to adapt the operation of treatment plants to the individual characteristics of the facility. A cozy office with heating, ventilation, lighting and a fire and security system is provided for the maintenance personnel. - Minimum operating costs.

Sludge dewatering is carried out using MDQ Esmil Tsurumi multi-disc screw dehydrators, which are characterized by low consumption of rinsing water and reagents. The unique design of the dewatering drum ensures its reliable and efficient operation for even 50,000 working hours, and the dehydrator requires minimum intervention by the maintenance personnel. - Compactness.

The Module D mechanical dewatering plant as a 20- or 40-feet container occupies only 15 or 30 m2 respectively! It can be easily deployed in a confined area of a wastewater treatment plant, a factory or even a marine vessel. - Mobility.

It is possible to use the dewatering plant both in stationary conditions and for sludge treatment at various facilities. The body of the installation is made based on a sea container with high strength and uniform dimensions, which makes it possible to transport equipment to the site by widely available modes of transport. - Possibility of quick modernization or productivity increase by installing additional dewatering drums in the installed dehydrator or by supplying additional modules.

- Additional options *.

The availability of a large number of additional options, such as control of various parameters of the reagent sludge treatment process, various degrees of automation, individual climatic performance, as well as additional equipment at the request of the client.

* See for an example of a complete on the tab Characteristics.

Technical and technological characteristics of mechanical dehydration complexes based on MDQ dehydrators

| MDQ Dehydrator Model | 20X | 40X | 50X |

|---|---|---|---|

| Capacity, m3/h | |||

| - raw sludge | 0.5 - 2.5 | 20 - 10 | 40 - 170 |

| - excess activated sludge | 1 - 4 | 3 - 15 | 5 - 30 |

| - excess activated sludge (thickened) | 0.3 - 2 | 1 - 5 | 2 - 10 |

| - aerobically stabilized activated sludge | 1 - 4 | 3 - 15 | 6 - 25 |

| - dairy wastewater sludge | 1 - 4 | 3 - 15 | 6 - 25 |

| - meat processing wastewater sludge | 2 - 6 | 6 - 25 | 10 - 50 |

| - cosmetics production wastewater sludge | 1 - 2 | 1.5 - 7 | 3 - 12 |

| Dewatering screw diameter, mm | 200 | 350 | 450 |

| Number of drums | 1 - 4 | 1 - 4 | 1 - 3 |

| Container size, ft | 20 | 20 - 40 | 20 - 40 |

| Module footprint, m2 | 16 | 16 to 32 | 16 to 32 |

| Installed power of equipment*, kW | 3 - 5 | 5 - 15 | 15 - 50 |

| Water consumption for flushing, l/h | 33 - 99 | 44 - 132 | 110 - 330 |

| Water consumption for flocculant preparation, l/h | 5 - 120 | 20 - 450 | 30 - 800 |

| Production material | AISI 304/316 | AISI 304/316 | AISI 304/316 |