Application

RKE bar screens are used in the process of preliminary mechanical wastewater treatment. Their primary function is the effective capture of solid contaminants before the wastewater is directed to subsequent treatment stages.

The use of screens helps protect downstream equipment from overload, mechanical damage and blockages, which translates into higher efficiency and greater operational safety of the entire treatment process.

Areas of application for ESMIL Bar Screens:

- municipal wastewater treatment plants,

- industrial wastewater treatment plants (including the processing industry),

- wastewater pumping stations.

Design range

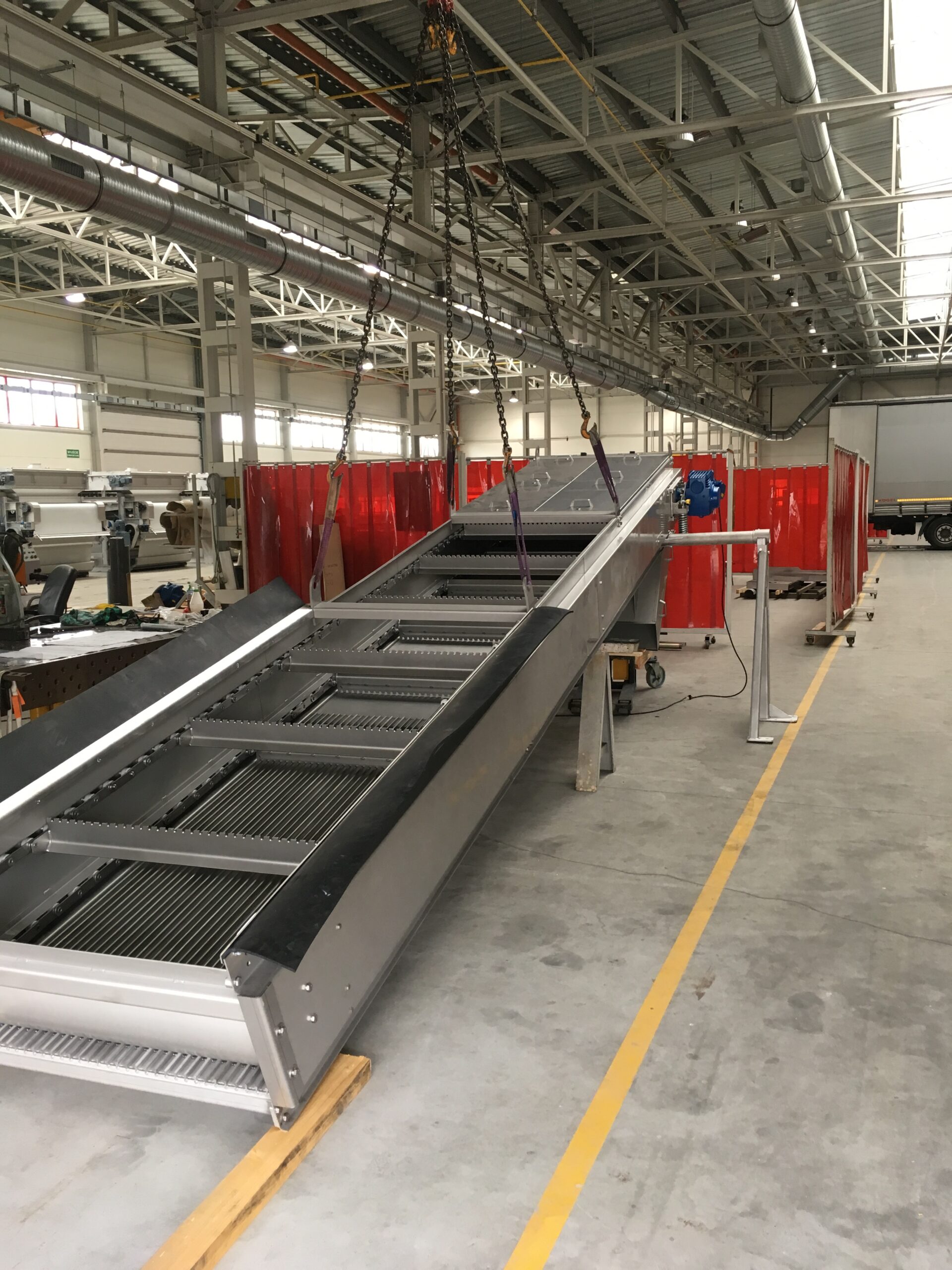

Height up to 15 m, width up to 3 m – depending on project requirements.

Technological advantages of ESMIL Bar Screens

- Wide range of available bar spacings (6–60 mm) allows precise adjustment of the screen to the characteristics of incoming solids.

- Water drop–shaped filter bar profile ensures low hydraulic resistance, increases throughput and prevents clogging between bars.

- Rotary mechanism and well-designed construction allow quick maintenance without dismantling the device or emptying the channel.

- Depending on the type of solids, the number and geometry of rakes can be adjusted, including the use of teeth of different sizes.

- Stainless steel construction (AISI 304 or AISI 316) ensures high resistance to aggressive wastewater environments.

- No rotating elements in the submerged area. The rake chains move along plastic guides, ensuring smooth operation and reducing wear.

- Electrical protection against overloads and voltage surges guarantees stability and safe operation.

- Automated control system enables flexible adjustment of the screen’s operating mode to wastewater levels in the channel or to a programmed schedule.

Construction of the ESMIL Bar Screen

Additional equipment

- SCP Screw Compacting Press – a device designed for washing and dewatering screenings. It enables significant volume reduction, thereby lowering transportation and disposal costs.

- Screw Conveyor – used for transporting materials generated during the wastewater treatment process, such as screenings, washed sand and dewatered sludge.