Application

RMB TP outside-in drum screens are used in the process of preliminary mechanical treatment of raw wastewater. Their primary function is the effective separation of solid contaminants before the wastewater is directed to subsequent technological stages.

They are particularly well suited for facilities with small and medium capacities, where precise removal of fine solid particles as well as organic and fatty contaminants is required.

Areas of application for ESMIL outside-in Drum Screens:

- wastewater treatment in the food industry,

- wastewater treatment in the processing industry,

- preliminary treatment of municipal wastewater.

Technological advantages of ESMIL Drum Screens

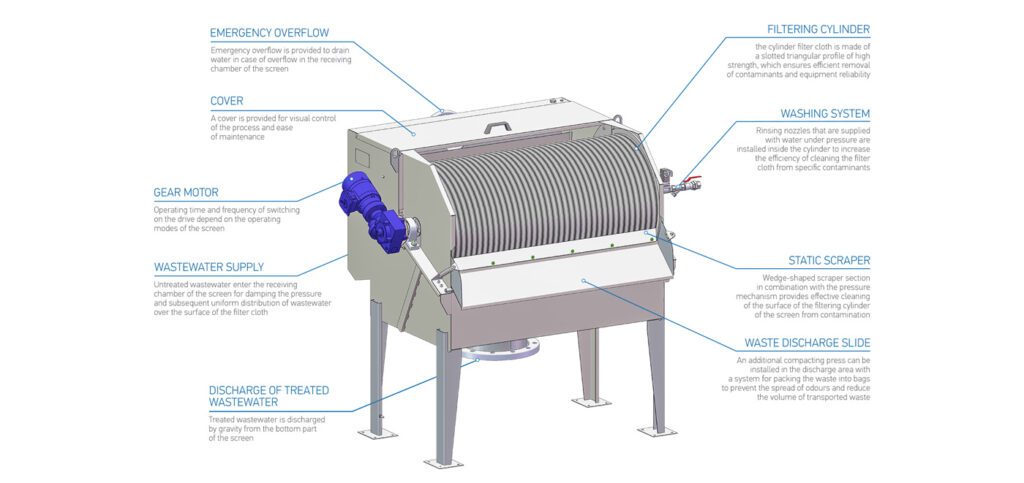

- Compact design – small dimensions of the unit (while maintaining high throughput) allow installation even in limited technical spaces.

- The triangular-profile filtering mesh design enables efficient removal of fine contaminants with particle sizes of 0.25 mm and larger.

- Scraper positioned on the drum surface mechanically removes accumulated solids from the filtering surface, ensuring continuous operation and reducing the risk of clogging.

- Internal spray nozzle system ensures thorough cleaning of the filtering surface and stable operation even in the presence of fats and petroleum compounds.

- Automated operation – the unit can work in different modes and can be easily synchronized with other elements of the technological installation.

- Integrated overflow system – the screen design includes an emergency overflow to prevent overfilling under hydraulic overload conditions.

- Electrical protection against overloads and voltage surges ensures stable and safe operation.

- Simple and well-thought-out construction provides easy access to all key components of the screen.

Construction of the ESMIL Drum Screen Outside-in

Additional equipment

- SCP Screw Compacting Press – a device designed for washing and dewatering screenings. It enables significant volume reduction, thereby lowering transportation and disposal costs.

- Screw Conveyor – used for transporting materials generated during the wastewater treatment process, such as screenings, washed sand and dewatered sludge.