Application

RSK step screens are used in the process of preliminary mechanical wastewater treatment. Their primary function is the effective capture of solid contaminants before the wastewater is directed to subsequent treatment stages.

The use of step screens helps protect downstream equipment from overload, mechanical damage and blockages, which translates into higher efficiency and greater safety of the entire treatment process.

Areas of application for ESMIL Step Screens:

- municipal wastewater treatment,

- industrial wastewater treatment plants.

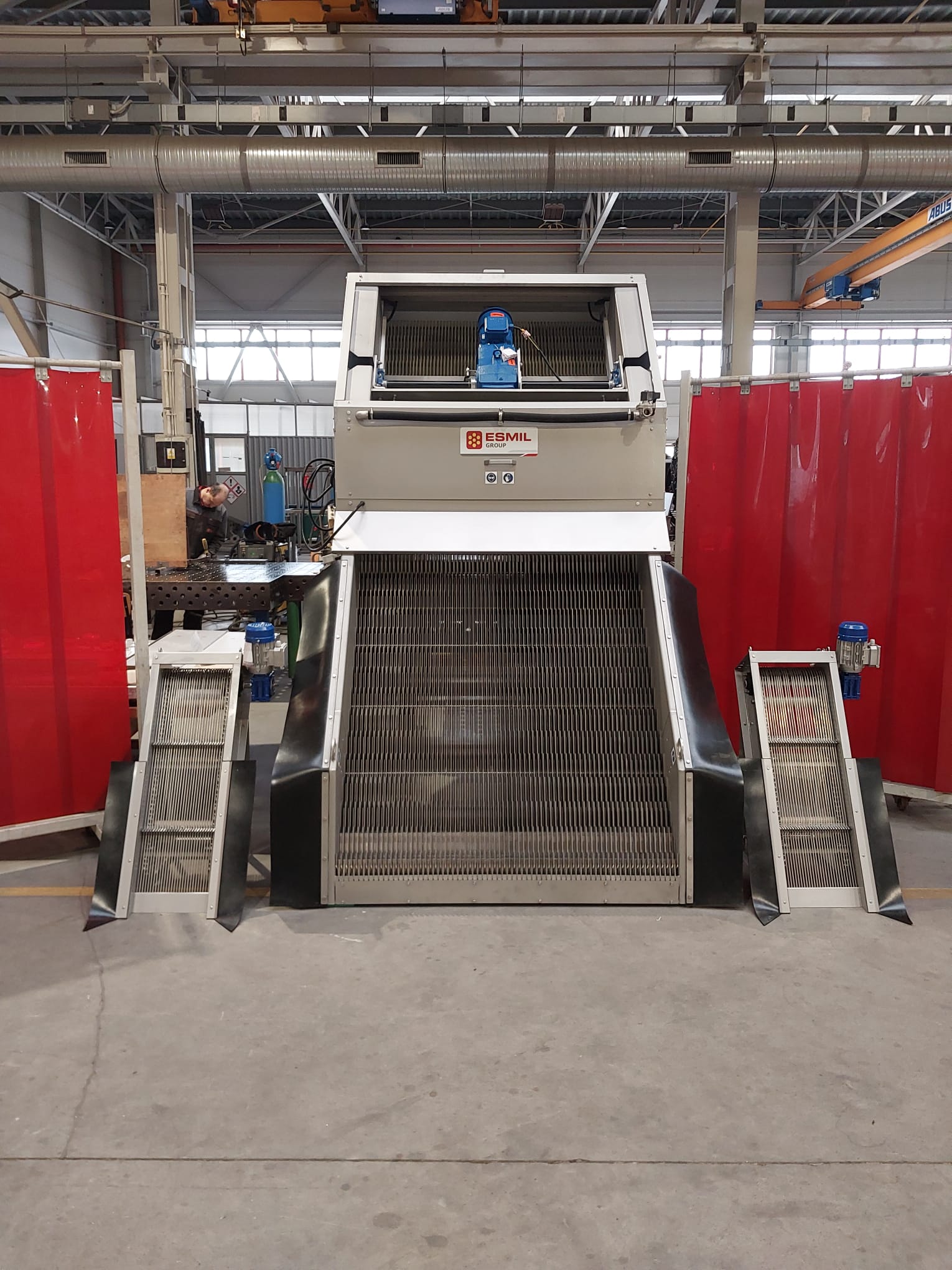

Construction of the ESMIL Step Screen

- SCP Screw Compacting Press – a device designed for washing and dewatering screenings. It enables significant volume reduction, thereby lowering transportation and disposal costs.

- Screw Conveyor – used for transporting materials generated during the wastewater treatment process, such as screenings, washed sand and dewatered sludge.